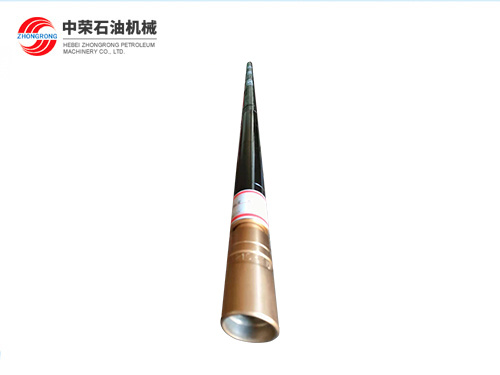

One trip whipstock

Classification:

Tag:

Mail:

One trip whipstock

One trip whipstock (or single trip whipstock) which can be run into a well, set, and operated from a window in the well casing by a single trip includes a milling tool attached to the upper end of a hydraulic whipstock to the lower end of which is attached a packer or anchor which can be set by appropriate means prior to detachment of the window casing milling from the hydraulic whipstock to initiate window formation.

Features

1. Design two rows of anchoring slips to ensure the whipstock set in the casing steadily and stably.

2. Apply 2-3 degrees ramp to make a relatively small dogleg degree at the window and ensure the drilling string pass through the window exit smoothly.

3. Optimal designed milling shoe assembly (including lead mill and dress mill) can achieve high milling speed, low milling torque and smooth window quality.

4. Orient with MWD or UBHO/GYRO available.

5. Only one trip to set whipstock, mill casing exit and drill rat hole.

6. Hydraulic system is retrievable.

We have a professional sidetracking technical team to provide sidetracking services.

Basic parameters and performance data.

| Casing OD, in | Whipstock | Casing window milling | Well deflection range, ° | Temperature range, ℃ | Setting method | |||||

| Whipstock type, mm | Whip angle, ° | Whip length, mm | Cambered face,mm | Casing window milling type, mm | Connecting thread | Cut weight, Kn | ||||

| 5 1/2"(φ139.7) | φ114x3280 | 3.2° | 1900 | φ125 | φ120x1050 | 2 7/8 IF | 40 | ≤40° | ≤200℃ | Directly pressure |

| 7"(φ177.8) | φ150x3960 | 3.2° | 2515 | φ165 | φ150x1150 | 3 1/2 IF | 60 | |||

| 9 5/8"(φ177.8) | φ210x4650 | 4° | 2650 | φ225 | φ215x1750 | 4 1/2 IF | 80 | |||

| Note: Stabilizer can be made according to customer’s special requirement. | ||||||||||

Get Quote

Note: Please fill in the following contact information, our experts will contact you within 24 hours on your request and provide a free purchase plan.