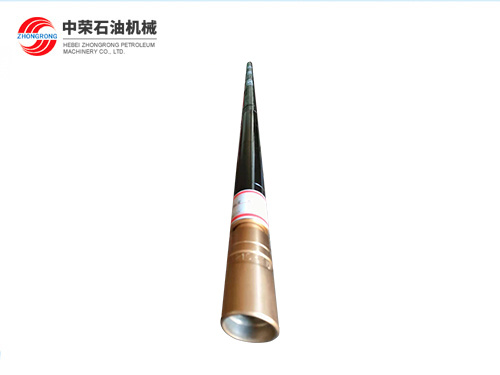

Whipstock

Classification:

Tag:

Mail:

Whipstock

The hydraulic whipstock produced by our company include ground spear anchoring and hydraulic anchoring. The hydraulic anchoring has the characteristics of azimuth accurate and anchor firmly. When the casing in the oil layer is seriously damaged or the oil layer collapses and is buried in sand, and the oil well can no longer be produced, in order to reduce the cost of drilling well, milling the casing and sidetracking a new wellbore by whipstock. The sidetracking tool mainly consist of whipstock and casing window milling .

Sheet 1、Basic parameters and performance data.

| Whipstock type | Casing OD, in | Anchor OD, in | Structure form | Whipstock length, | Connecting thread |

| in | |||||

| DXQ102 |

5〃 (φ127) |

4 |

common(direct flushing) |

3.3 | 2 3/8REG |

| DXQ102F |

Leak proof(counter flushing ) |

3.8 | |||

| DXQ114 |

5 1/2〃 (φ139.7) |

4.5 | common(direct flushing) | 3.5 | 2 7/8REG |

| DXQ114F |

Leak proof(counter flushing ) |

4 | |||

| DXQ136 |

65/8〃 (φ168.28) |

5.35 | common(direct flushing) | 4 | 3 1/2REG |

| DXQ136F | Leakproof(counter flushing ) | 4.5 | |||

| DXQ138 | 5.35 | common(direct flushing) | 4 | 3 1/2REG | |

| DXQ138F | Leak proof(counter flushing ) | 4.5 | |||

| DXQ146 |

7〃 (φ177.8) |

5.75 | common(direct flushing) | 4 | 3 1/2REG |

| DXQ146F | Leak proof(counter flushing ) | 4.2 | |||

| DXQ150 | 5.75 | common(direct flushing) | 4 | 3 1/2REG | |

| DXQ150F | Leak proof(counter flushing ) | 4.2 | |||

| DXQ160 | 7 5/8〃 | 6.3 | common(direct flushing) | 4.2 | 3 1/2REG |

| (φ193.68) | |||||

| DXQ210 | 9 5/8〃 | 8.27 | common(direct flushing) | 4.6 | 4 1/2REG |

| (φ244.5) | |||||

| DXQ300 |

13 3/8" (φ339.7) |

11.8 | common(direct flushing) | 5.6 | 4 1/2REG |

| DXQ300F | Leak proof(counter flushing ) | 5.8 |

3. Two trips whipstock

In order to better satisfy the need of double casing or sidetracking operations windows on the long department.forward section, our company specially developed two-cylinder whipstock. This product is mainly directed against the long cycle and difficult of construction. Adopts structurally dual hydraulic cylinder, four groups slip, internal through special connection structure, which can guarantee the liquid sealing and pressure flow. Two groups of hydraulic cylinder work independently, four groups slip directional chucking and ensure all closure process firmly accurate, during the construction of safe and reliable.

Sheet 2、Basic parameters and performance data.

| Spec. and product code | Available casing | Structure form | Overall size(mm) | Window length(mm) | Fit for the inclination of well | Fit for the well temp. | Seat packing method | Connecting thread |

| DXQ102H |

5〃 (φ127) |

common(direct flushing) | φ102×4140 | 1600~1800 | ≤40° | ≤200℃ | Bowling press | 2 3/8REG |

| DXQ102FH | Leak proof(counter flushing ) | Φ102×4650 | Direct press | |||||

| DXQ114H |

5 1/2〃(φ139.7) |

common(direct flushing) | φ114×4380 | 1800~2000 | ≤40° | ≤200℃ | Bowling press |

2 7/8REG or NC31★ |

| DXQ114FH | Leak proof(counter flushing ) | φ114×4890 | Direct press | |||||

| DXQ136H |

65/8〃(φ168.28) |

common(direct flushing) | φ136×4870 | 2000~2200 | ≤40° | ≤200℃ | Bowling press |

3 1/2REG or NC38★ |

| DXQ136FH | Leak proof(counter flushing ) | φ136×5380 | Direct press | |||||

| DXQ138H | common(direct flushing) | φ138×4870 | 2000~2200 | ≤40° | ≤200℃ | Bowling press |

3 1/2REG or NC38★ |

|

| DXQ138FH | Leak proof(counter flushing ) | φ138×5380 | Direct press | |||||

| DXQ146H |

7〃(φ177.8) |

common(direct flushing) | φ146×5000 | 2400~2500 | ≤40° | ≤200℃ | Bowling press |

3 1/2REG or NC38★ |

| DXQ146FH | Leak proof(counter flushing ) | φ146×5200 | Direct press | |||||

| DXQ150H |

7〃(φ177.8) |

common(direct flushing) | φ150×5000 | 2400~2500 | ≤40° | ≤200℃ | Bowling press |

3 1/2REG or NC38★ |

| DXQ150FH | Leak proof(counter flushing ) | φ150×5200 | Direct press | |||||

| DXQ160H |

7 5/8〃(φ193.68) |

common(direct flushing) | φ160×5200 | 2500~2700 | ≤40° | ≤200℃ | Bowling press |

3 1/2REG or NC38★ |

| DXQ210H |

9 5/8〃(φ244.5) |

common(directflushing) | φ210×5600 | 2700~3000 | ≤40° | ≤200℃ | Bowling press |

4 1/2REG or NC50★ |

4. Cambered whipstock

Incline of cambered whipstock is arc surface, And after super hardening treatment, the anastomosis of incline and the cone mill bit is high, centralizer effect is good, open Windows custom, sleek, azimuth precise, During construction, easy to control pressure, reduce suppressing drill and jumping of drill, reduced the downhole accident happening.

5. Recycling whipstock

With the improvement of directional well and horizontal well technology, as the extension and development of directional well technology, multilateral wells have received more and more attention. The retrievable whipstock is a key tool for multilateral well drilling technology and plays a vital role in the drilling and completion of multilateral wells.

The retrievable whipstock developed by our company has the characteristics of easy operation, firm seat seal, high recovery success rate, and reusability.

The retrievable whipstock is divided into three parts: whipstock, circulating well flush valve and fishing tool.

Sheet 3、Basic parameters and performance data.

| Casing OD, in | Whipstock tool | Circulating well flushing tool | Recycling tool | Rake of well | Temperature of well | Hydraulic anchoring method | |||

| Type | Angle (°) | Length (mm) | OD, in (mm) | Type | Type | ||||

| 51/2” | Φ118x3490 | 3.2. | 1900 | Φ125 | Φ114x630 | Φ118x3540 | ≤90° | ≤200℃ | Direct press |

| 7” | Φ150x4050 | 3.2. | 2515 | Φ165 | Φ150x710 | Φ150x4130 | |||

| 95/8” | Φ210x4850 | 4 | 2600 | Φ225 | Φ210x820 | Φ210x4960 | |||

Get Quote

Note: Please fill in the following contact information, our experts will contact you within 24 hours on your request and provide a free purchase plan.